EXPANDABLE GAS TREATMENT FACILITY

REUSING EXISTING EQUIPMENT

LOCATION: Carthage, TX

MARKET: Natural Gas Processing

THE CHALLENGE

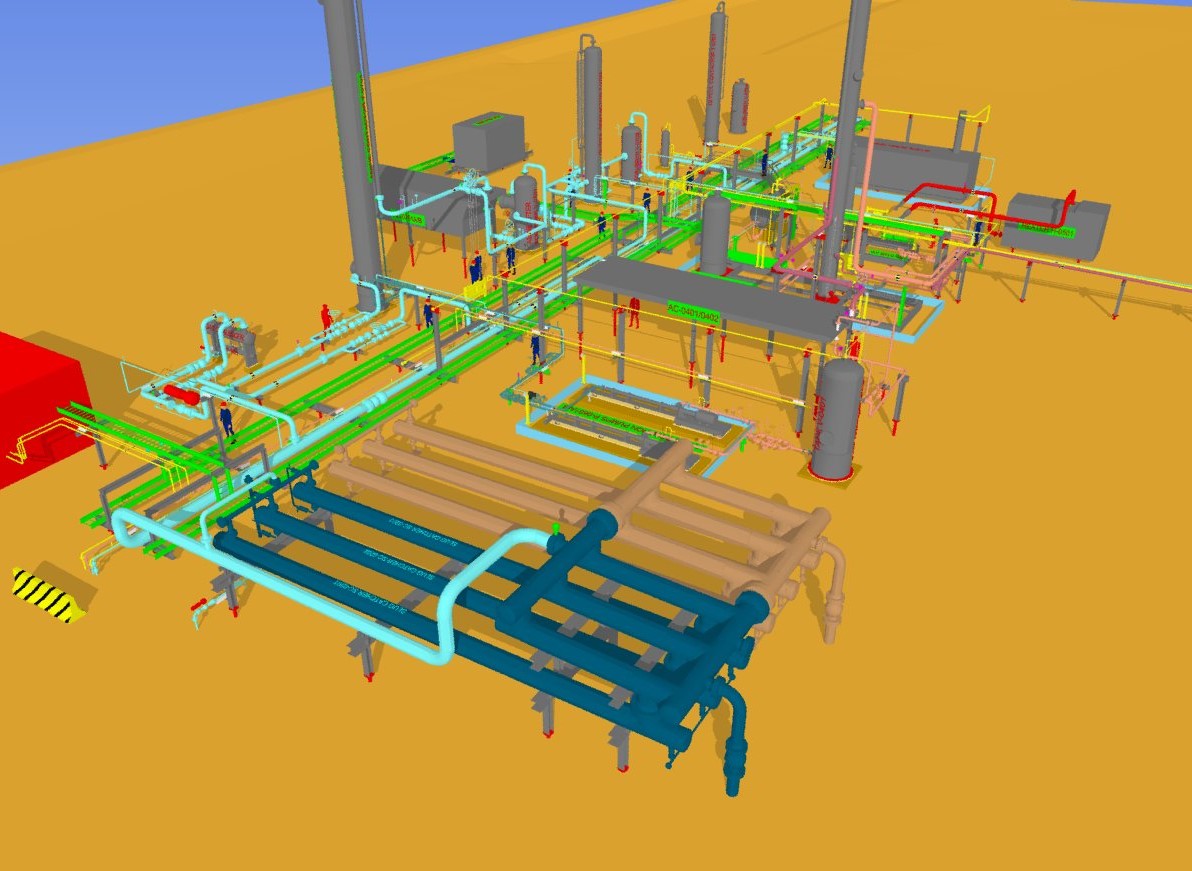

A new gas producer presented an opportunity for our Client to gather their gas. This gas required treatment before meeting pipeline sales gas specifications for the area. The producer insisted on a tight time frame for being ready to receive gas. Fortunately, our Client had idle equipment available for gas sweetening and gas dehydration at a site that was decommissioned. By using this existing equipment at the new site, up to 80 MMSCFD could be processed initially, plus future expansion capabilities up to a total of 200 MMSCFD.

THE SOLUTION

CANUSA EPC visited the decommissioned site to verify the available major equipment and understand the power and controls package. Engineered valves and process piping that might be reused or refurbished were identified.

Developing a Plan:

- Evaluated the capacity of the existing amine treater package and dehydration equipment

- Identified new equipment required for the balance of the facility

- Developed design basis to capture required project technical requirements

Sourcing New Equipment:

- High-pressure inlet slug catcher

- BTEX condenser and combustor

- Storage tanks

- Control room building and PLC

Execute Value Engineering and Procurement to Accelerate the Project Schedule:

- PSV calculations for, and safety review of, all existing and new equipment

- Design of finger-type inlet slug catcher versus procurement of high-pressure vessel

- Evaluate and recommend helical pile foundation deployment

- Sourced major electrical tie-in equipment

THE RESULTS:

- Deployed pile foundations to remove concrete cure time requirements from the construction schedule

- Utility and electrical equipment sourced and removed from the critical path

- Mechanical design allows for the future expansion of the facility throughput to 200 MMSCFD