NATURAL GAS PROCESSING

200 MMSCFD System Expansion – EI&C System Design & Fabrication

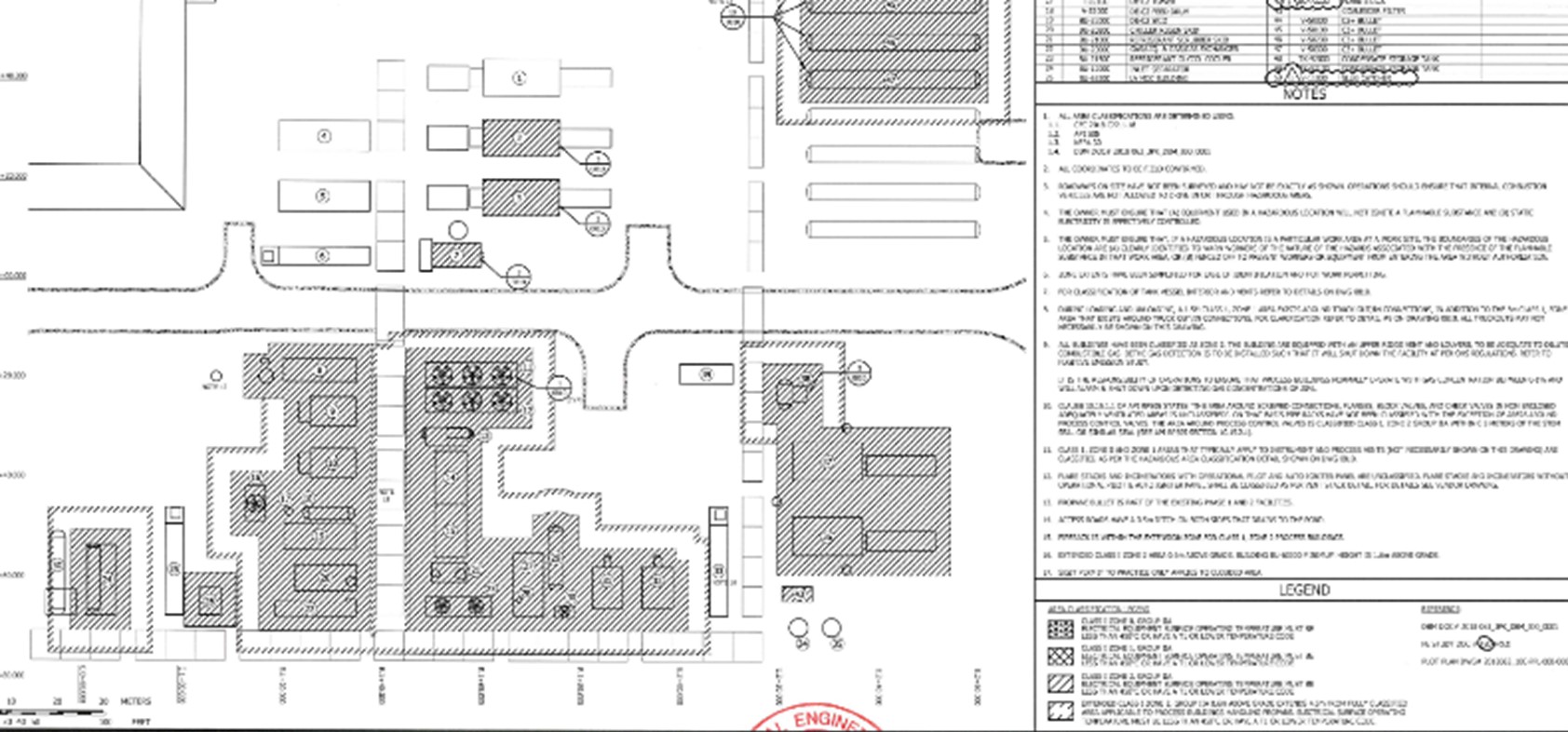

LOCATION: Grande Prairie, AB

MARKET: Natural Gas Processing

THE CHALLENGE

Our Midstream Client had an existing 180 MMSCFD gas processing facility and wanted to add another 400 MMSCFD processing equipment across two new processing trains. The new expansion was required to have its own inlet, flare, utilities and gas processing trains. There was a desire to leverage the existing site electrical and control systems for the expansion.

THE SOLUTION

- Lump sum engineering

- Lump sum DeltaV configuration and commissioning

- Lump sum supply of (4) PDC buildings including MV and LV electrical systems and control systems

- DeltaV control cabinets and 9 RIO cabinets

- Project included 14 MW of prime generations via solar turbines

- 1200 IO point systems

- Integrated FAT testing in Calgary

- On-site pre-commissioning and commissioning

THE RESULTS:

- Electrical packages arrived before the mechanical system

- Lowered construction costs with a distributed network and electrical system