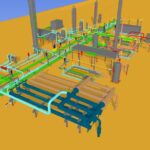

NGL FRACTIONATION TRAIN

HYDROCARBON STABILIZATION

LOCATION: Bantry, AB

MARKET: Natural Gas Processing

THE CHALLENGE

Development plans and contractual obligations required the Client to receive and process additional NGL volumes from truck-in through their existing fractionation process. This would allow the Client to capture the value of the fractionation products in the local market that would otherwise be passed down the value chain. The current process was limited in NGL storage volumes, tower capacities, re-boiler duties and product recoveries.

THE SOLUTION

CANUSA EPC provided, under a lump sum contract, value engineering and definition for the Client’s requirements.

- Simulation through ProMax and utilized raw data to evaluate the sizes and internals of the current equipment

- Completion of a What-If to assess the design impact of handling impurities (sour and water) on the front end

- Operational improvements

- Resolved DeC2 liquid level flooding

▪ De-bottlenecked DeC3 and DeC4 tower pressures

▪ Ensured product purities year-round

▪ Upgraded the storage area for increased volumes and trucking logistics

▪ Surge drum analysis to support inlet fluctuations

▪ Simplified product cooling design and controls - Procurement plan development to support budgeting

▪ Fractionation package

▪ NGL bullet, transfer pump skid and vapor return compressor - Repurpose of existing equipment to leverage in new design

▪ Heat medium exchange

▪ Fractionation coolers and reflux system

▪ Product storage and loadin

THE RESULTS:

CANUSA EPC completed a capacity study and found a low-cost option that would provide for future expansion.

- NGL fractionation capacity of 2,000 BPD with turndown to 240 BPD

- TIC of $5MM for installation of the equipment

- C3 and C4 product purities of 99%+

- C5 product purity of 650 kg/m3 and 5% C4

- Integration of 1 MMBTU/hr of waste heat to reduce OpEx as well as cooler and re-boiler duties