NATURAL GAS PROCESSING

Cryogenic Plant Optimization

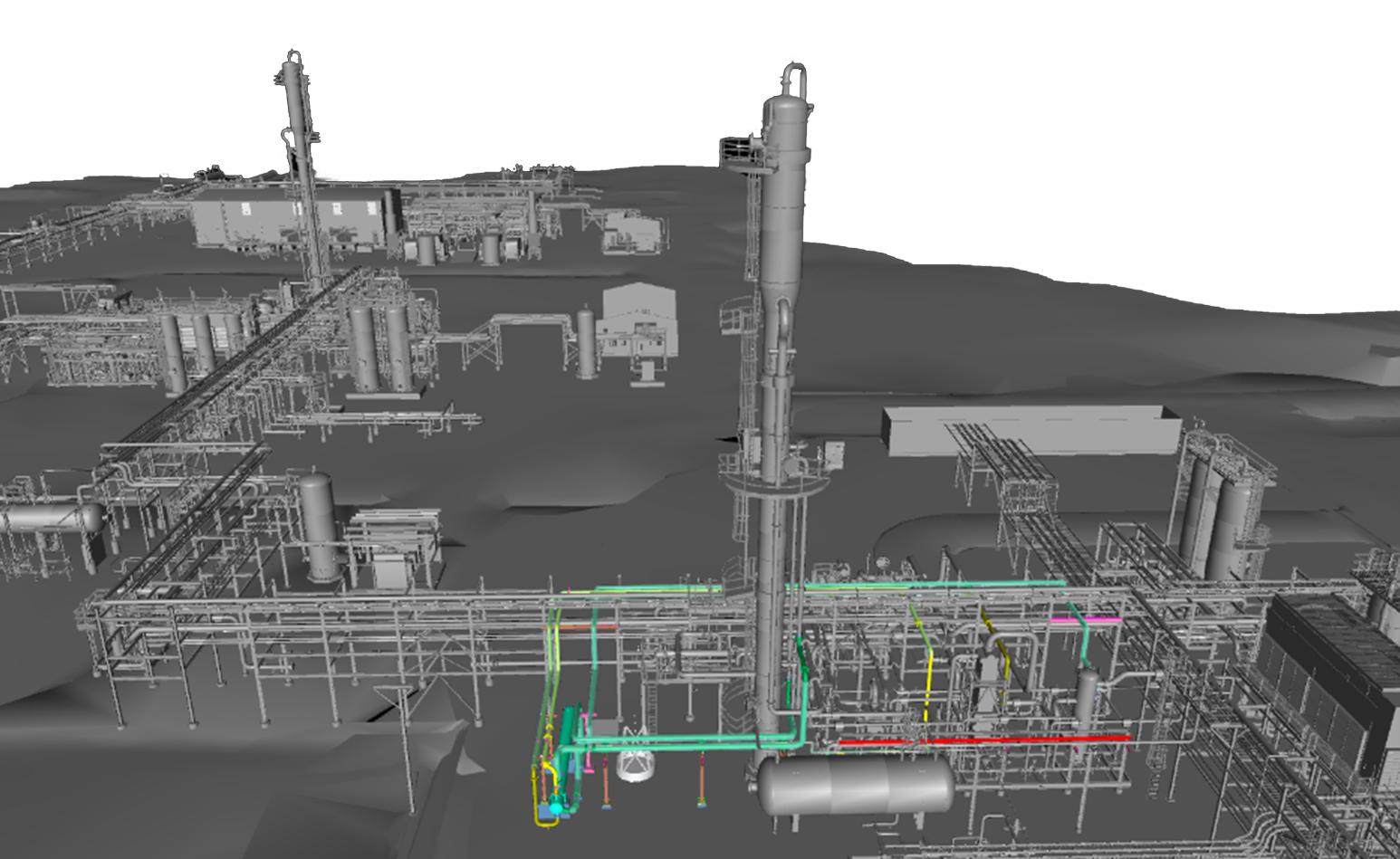

LOCATION: Vernal, UT

MARKET: Natural Gas Processing

THE CHALLENGE

CANUSA EPC’s Client needed to determine the capability of throughput capacity for a dual-train plant related to rejection and recovery operations. Due to the minimum operating costs of the plant, the Client wanted to evaluate which major equipment could be upgraded to allow single or dual-train operations. Along with restriction conditions, the client desired to understand nameplate operating limits and applicable constraints.

THE SOLUTION

CANUSA EPC conducted a debottlenecking study to evaluate throughput limiting conditions related to various operating limits for pieces of equipment like guard beds, mole sieves, heat exchangers, towers, etc. Along with equipment considerations, CANUSA EPC ran scenarios for the rejection and recovery operations.

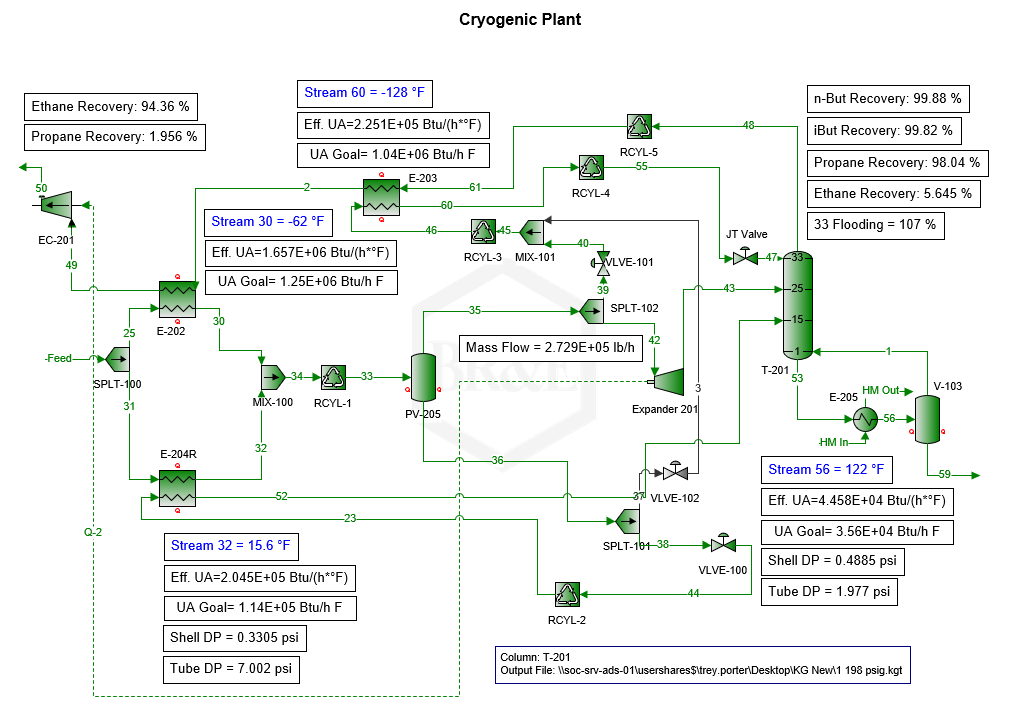

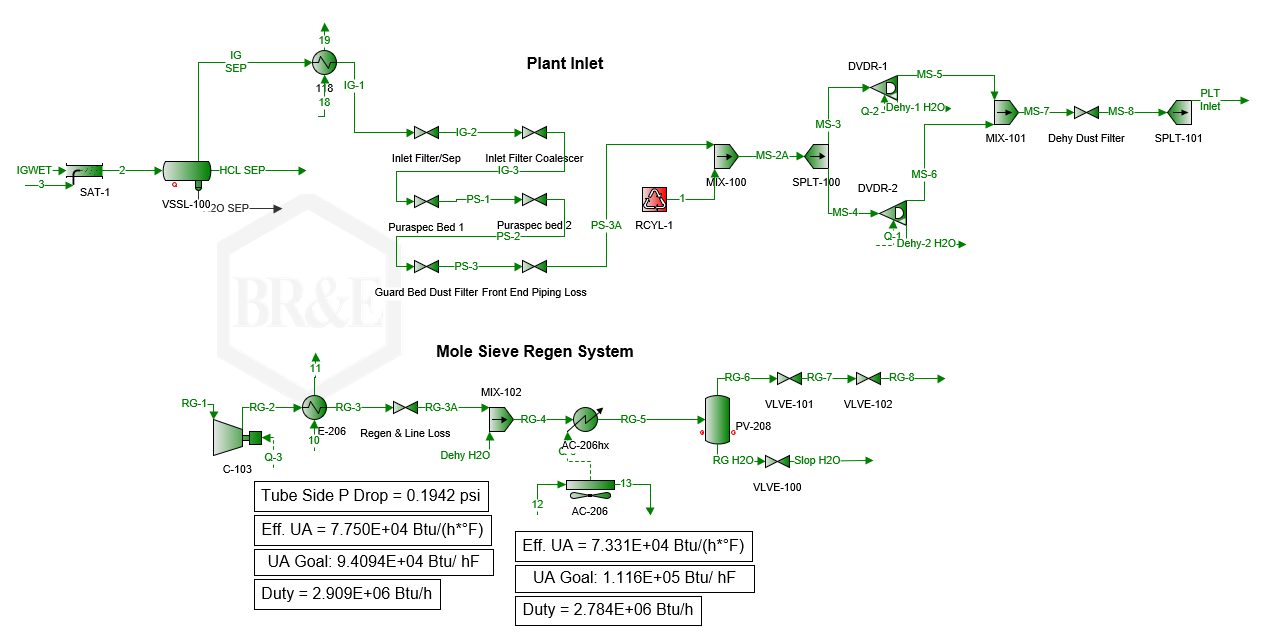

Process models of the major equipment in ProMax:

- Modeled cryogenic process for rejection and recovery modes

- Engaged vendors to determine plant inlet pressure drops through filters/guard beds

- Simulated mole sieve regeneration/dehydration loops

- Evaluated residue gas compression and heat content

- Determined heat transfer properties for exchangers/aerial coolers

Debottleneck Evaluation:

- Evaluated key equipment results to remain within equipment limits

- Tower flooding within KG Tower software

- Convective heat transfer for heat exchangers and aerial coolers

- Dehydration media, cycle times, and saturation for mole sieve units

- NPSHa vs. NPSHr for product and heat-medium pumps

- Mass flow for expander-compressors

- Compressor HP and available head capabilities

- Evaluated nozzle momentum with K-factors and pressure drops across all equipment

- Evaluated liquid retention time and vapor entrainment for vessels

- Evaluated the effect on recoveries as plant inlet flow increases

THE RESULTS:

- Determined minimum requirements to increase the throughput of each train by 20 MMSCFD

- Summarized for operations major equipment restrictions for both recovery and rejection modes

- Worked with filter vendors to determine maximum operating limits based on filter components