CRYOGENIC ELECTRICAL SYSTEM

DESIGNING FOR LOWER INSTALLED COST

LOCATION: Douglas, WY

MARKET: Natural Gas Processing

THE CHALLENGE

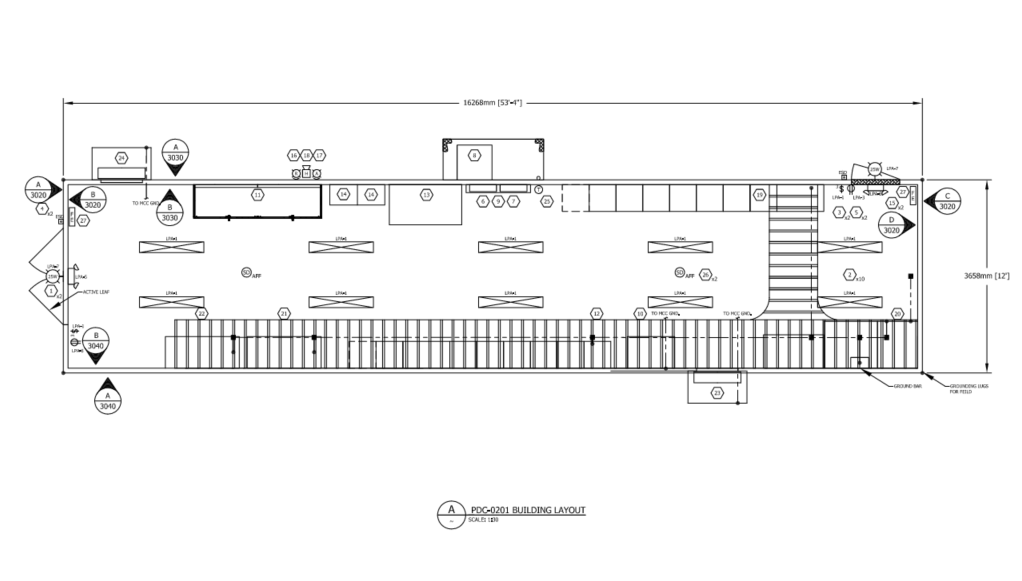

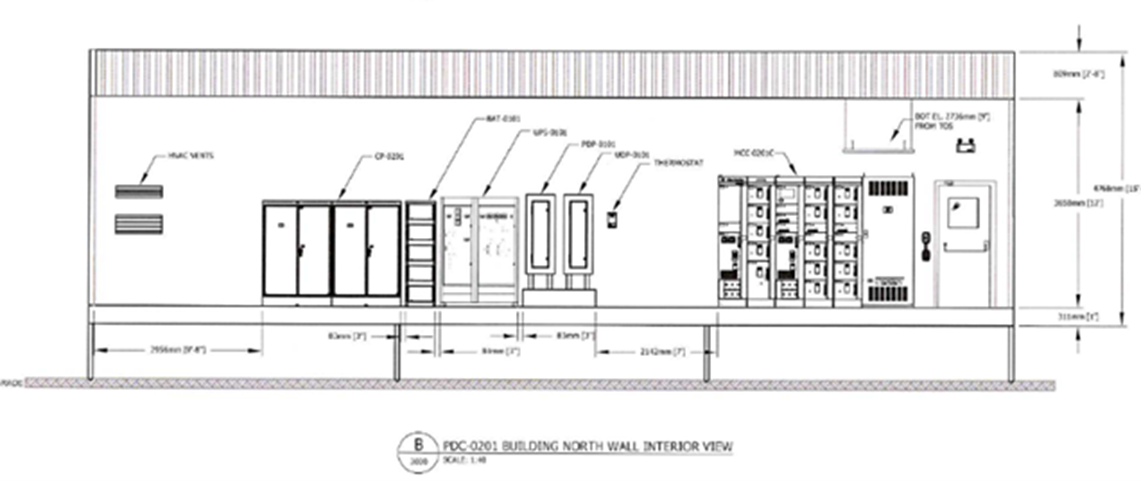

Our Midstream Client required an electrical system consisting of medium and low voltage PDC buildings as part of their 200 MMSCF/day cryogenic facility which was executed as an EPC model with a large packager. There was a desire to provide an integrated motor control system with the site control platform, but also distribute the system to lower the total installed cost of the package.

THE SOLUTION

Designing for Construction:

- Designing for Construction

• The electrical system was designed to minimize cable runs by placing the buildings closer to the equipment

• Distributing the electrical system into multiple buildings provided ease of transport and unloading and allowed for staged construction

• Integration of the PDC and control system minimized onsite interconnects

Executing to Deliver on Cost & Schedule:

- Structured a Lump sum supply of (4) PDC buildings including MV and LV systems and control systems to control costs

- Selected sparing capacity on MCC lineups to accommodate changes from the process/mechanical team

- Executed integrated testing before shipment to ensure minimal onsite changes

THE RESULTS:

- Low voltage buildings arrived before select mechanical packages allowing for electrical to execute in parallel to mechanical

- Allowed for addition of VFDs from late changes to the design

- Bottom entry connections lowered installation costs