TANK VENTING EMISSIONS REDUCTION

OOOO(b) Compliance / Methane Reduction

LOCATION: Harrison County, TX

MARKET: Emissions Reduction / OOOO(b)

THE CHALLENGE

The Client was venting excessive vapors from their produced water tank battery due to higher operating pressure in their inlet separator. Operations had determined that the pressure drop between the slug catcher and the storage tank was resulting in entrained gas venting above OOOO(b) limits.

THE SOLUTION

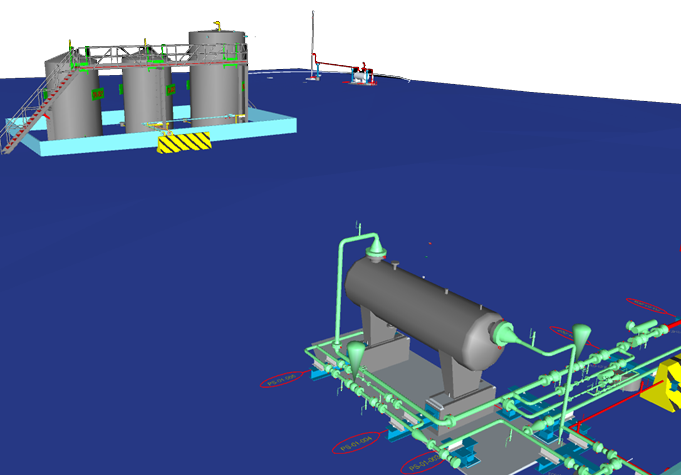

CANUSA EPC provided engineering and design to install an emission control device. An intermediate knockout drum and combustor were added to the facility. Liquids were routed from the slug catcher to the lower-pressure intermediate knockout, allowing more gases to flash off before sending the remaining liquids to the water tanks. All flashed gases were sent to the combustor.

Engineering

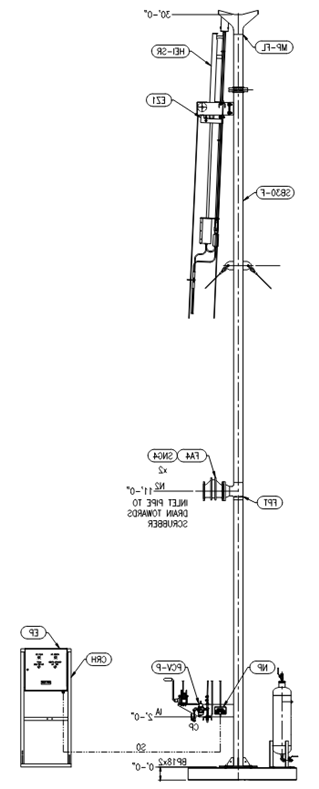

- Flare specification

- Re-purposed knockout drum evaluation

- Instrumentation and control systems added

- Saddle design and flare guy wire anchoring solution

Design

- 3D Modeling of piping, structural steel, and foundations

- Piping isometrics

- Pipe support and foundation details

THE RESULTS

Reduction in vented vapors from the tank battery

- Reduced direct venting methane by 10 TPY

- Alternative solution for recycle of entrained gas to inlet

- Compliance with OOOOb section 60.5365b(e)