NATURAL GAS GATHERING

Designing for Future Plug-and-Play

LOCATION: USA

MARKET: Natural Gas Gathering

THE CHALLENGE

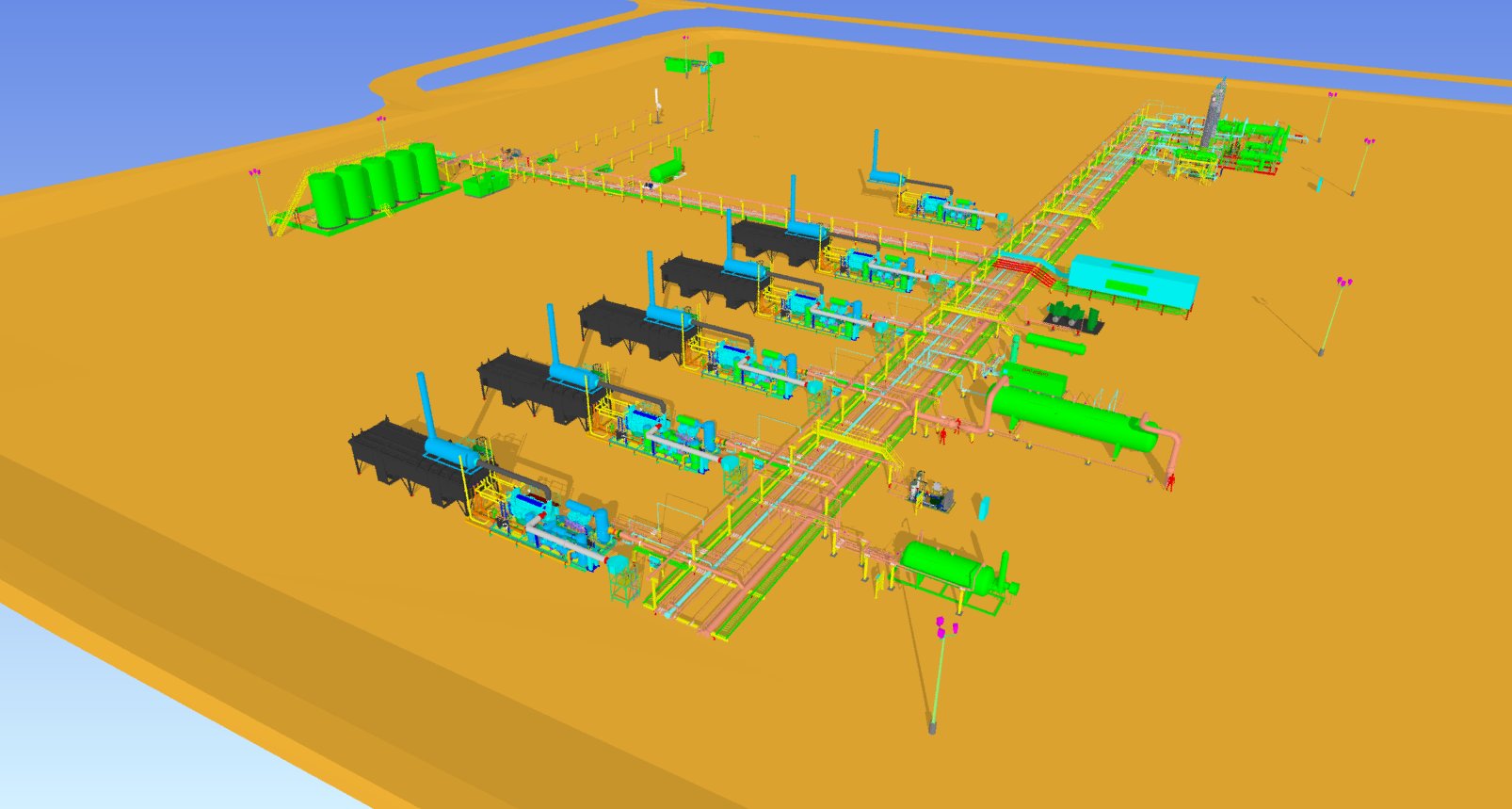

Additional gas production in the basin required our client to build a new compressor station, doubling the client’s compression capacity in the area from 120 MMscfd to 240 MMscfd. Due to the increasing CO2 content of the gas in the basin, the new station needed to include future Amine gas treatment in addition to gas dehydration. Functionality for gas blending from other high-pressure inlet sources with the sales gas was required to meet CO2 content and sales gas specifications in the short term. The client also wanted functionality to be able to combine low-pressure and high-pressure liquid products through a single sales pipeline.

THE SOLUTION

CANUSA EPC provided full discipline engineering to develop the construction packages for the client.

Developing a Plan to Meet Client Expectations:

- Leveraged the client’s previous compressor station design from CANUSA EPC

- Identified operational improvements for the new station

Sourced New Equipment:

- Low Pressure Inlet Slug Catcher

- Heater Treater

- High Pressure 3 Phase Separator

- Pipeline Pumps

- Motor Control Center Building

Execute Value Engineering to Support the Project Schedule:

- Redesigned layout for Glycol Heater Package

- Sized VRU package for expansion

- Specified switchgear and MCC equipment to remove from the critical path

- Reduced the height of the slug catcher package to lower site construction costs

THE RESULTS:

Provided Construction Package with Designs for Future Expansion

- Future site compressor additions require no additional mechanical design

- Design allows for additional inlets and Amine unit

Operations Improvements

- Consolidated low-pressure inlets to allow for a single slug catcher vessel

- Addressed issues with high-pressure drains

- Improved isolation, access, and piping for compressor packages