CENTRAL TANK BATTERY EXPANSION

Managing Upgrades and Regulations

LOCATION: Walden, CO

MARKET: Oil Processing and Storage

THE CHALLENGE

The Client was operating an existing Central Tank Battery with an existing separator and heater treater onsite for servicing the production facilities. This CTB was also the sales point for the gas from the production facilities. The Client wanted to increase the storage capacity onsite by 5000 BBL and add Vapor Recovery Units to meet tank emissions requirements. There was also a need to increase the inlet capacity to treat production for two new pads, targeting on line production shortly after the expansion of storage.

THE SOLUTION

CANUSA EPC first engaged with site visits to understand the existing infrastructure onsite and determine how the operations team had previously built the existing assets.

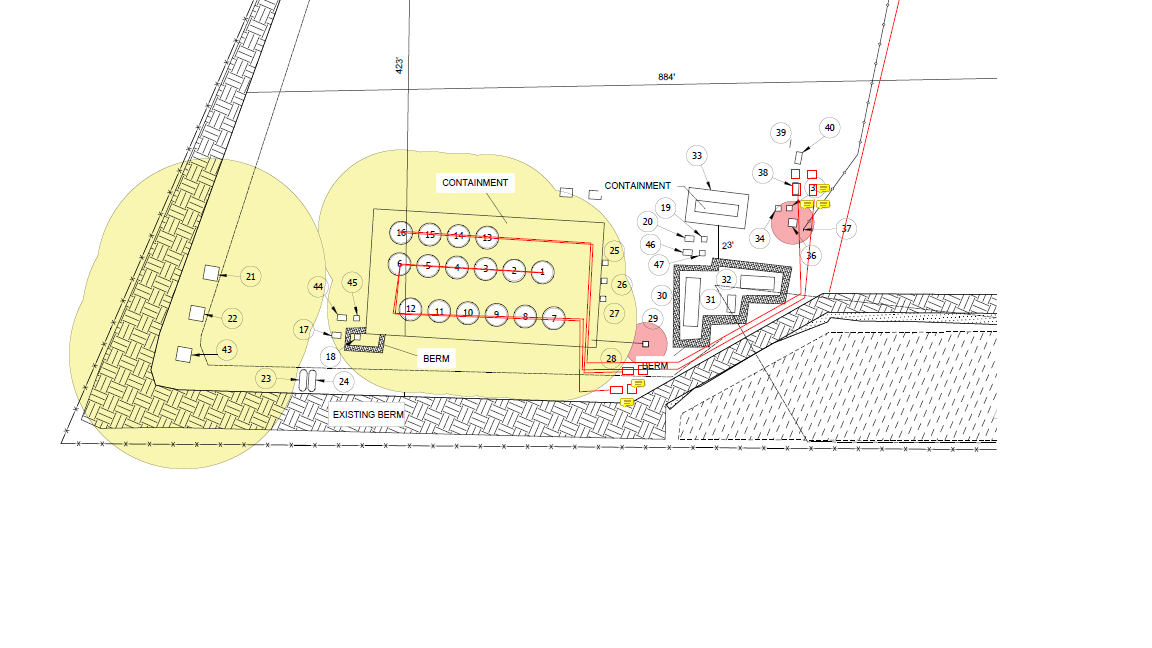

Our team provided as-built documentation of the existing facilities after the completion of a site visit. The construction design scope included:

Engineering:

- Facility plot plans and containment sizing for new tanks

- P&IDs of the facility

- Generation of pipe valve and fitting material based on the P&IDs

- Mechanical tie-in of a new VRU to meet Colorado AQCC Reg 7

- Area classification updates

- Single line updates

- Design of an electrical system for the expansion

- Electrical

- Controls

- Instrumentation

THE RESULTS:

Design and expanded two Central Tank Batteries

Designed expansion of an existing production facility and a new greenfield pad

Reusable equipment

- Provided onsite support of equipment walkdown for existing package redeployment

Designing for expansion capacity

- 900 barrels of added field production

- Existing electrical systems were evaluated to handle future needs for pumps and VRU packages