MULTI-WELL PURIFICATION BATTERY

Portable Field Processing

LOCATION: Holbrook, AZ

MARKET: Helium Processing

THE CHALLENGE

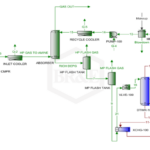

The client wanted a processing facility to be built where a raw gas inlet from four wells would be separated into a helium product with a 99.9+% purity, with future expansion in mind. A few of the challenges the client faced included the implementation of multiple wells into the facility, a desire for a portable system, and the need to generate power onsite with no fuel sources readily available.

THE SOLUTION

CANUSA EPC first engaged by performing an initial FEED study to identify what the scope of the project would need to be, and what would be required to make the client’s requests possible. After the FEED study, we provided full-service EPCM support.

- Project management

- Procurement & expediting of equipment

- Facility process design & engineering

- PHA & safety analysis

- Facility 3D Modeling, piping & instrument design

- Power generation & distribution

- Grading plan & pile layout

- Structural design & engineering

- Major equipment factory acceptance testing

- Controls programming support

- Construction support

THE RESULTS:

Capacity & Purity

- Facility provides 5 MMSCFD inlet capacity and sales product purity of up to 99.996% helium, or grade H4.6 helium utilizing a PSA system.

Portable Capability

- Fully-skidded, mobile equipment in sea-can structure allows the Client to reuse and relocate the facility wherever it is needed.

Power Generation

- Onsite power was generated with a compressed natural gas service while a renewable energy system was constructed.