COMPRESSOR STATION EXPANSION

Designing for future plug & play

LOCATION: Wyoming

MARKET: Natural Gas Gathering

THE CHALLENGE:

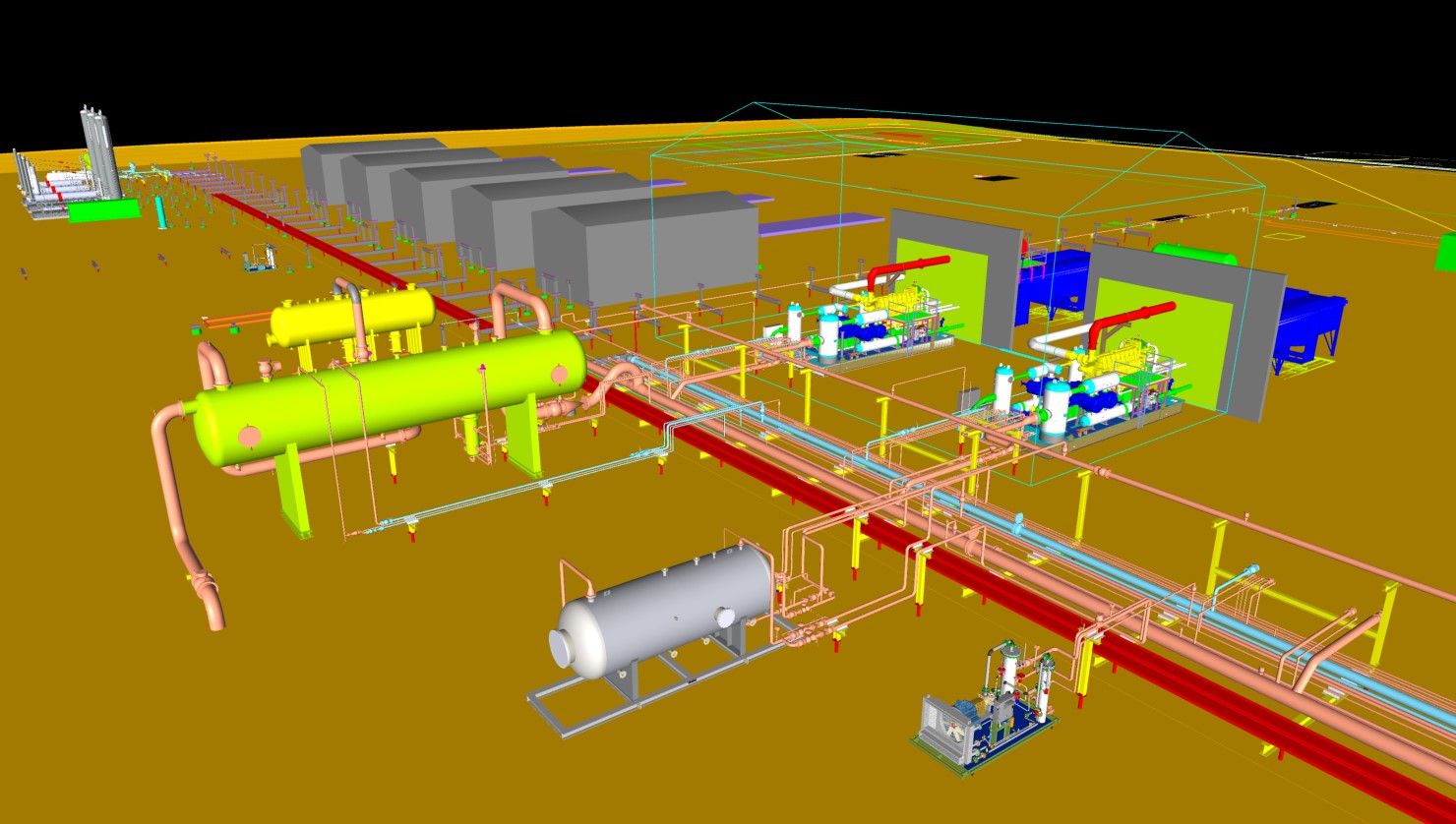

Growing gas production necessitated our client expand one of their compressor stations, doubling the capacity and total installed horsepower. The original low-pressure inlet was updated to allow for multiple inlets to feed gas compression and dehydration. The high-pressure inlet was modified to allow for blending should it need additional dehydration. Late into execution of the project, the existing high-pressure 3-phase separator was upsized to improve liquid removal and dehydration performance.

THE EXECUTION

Develop a Plan

• Executed onsite visits and as-built documentation of existing facility

• Reviewed operational improvements for the expansion

• Developed design basis to capture required project technical requirements

Source New Equipment

• Low-Pressure Inlet Slug Catcher

• High-Pressure 3-Phase Separator

• Motor Control Center (MCC) Expansion

Execute Value Engineering to Support the Project Schedule

• P&ID generation

• Equipment evaluation

• PSV sizing calculations and safety review

• Engineered Valve specification

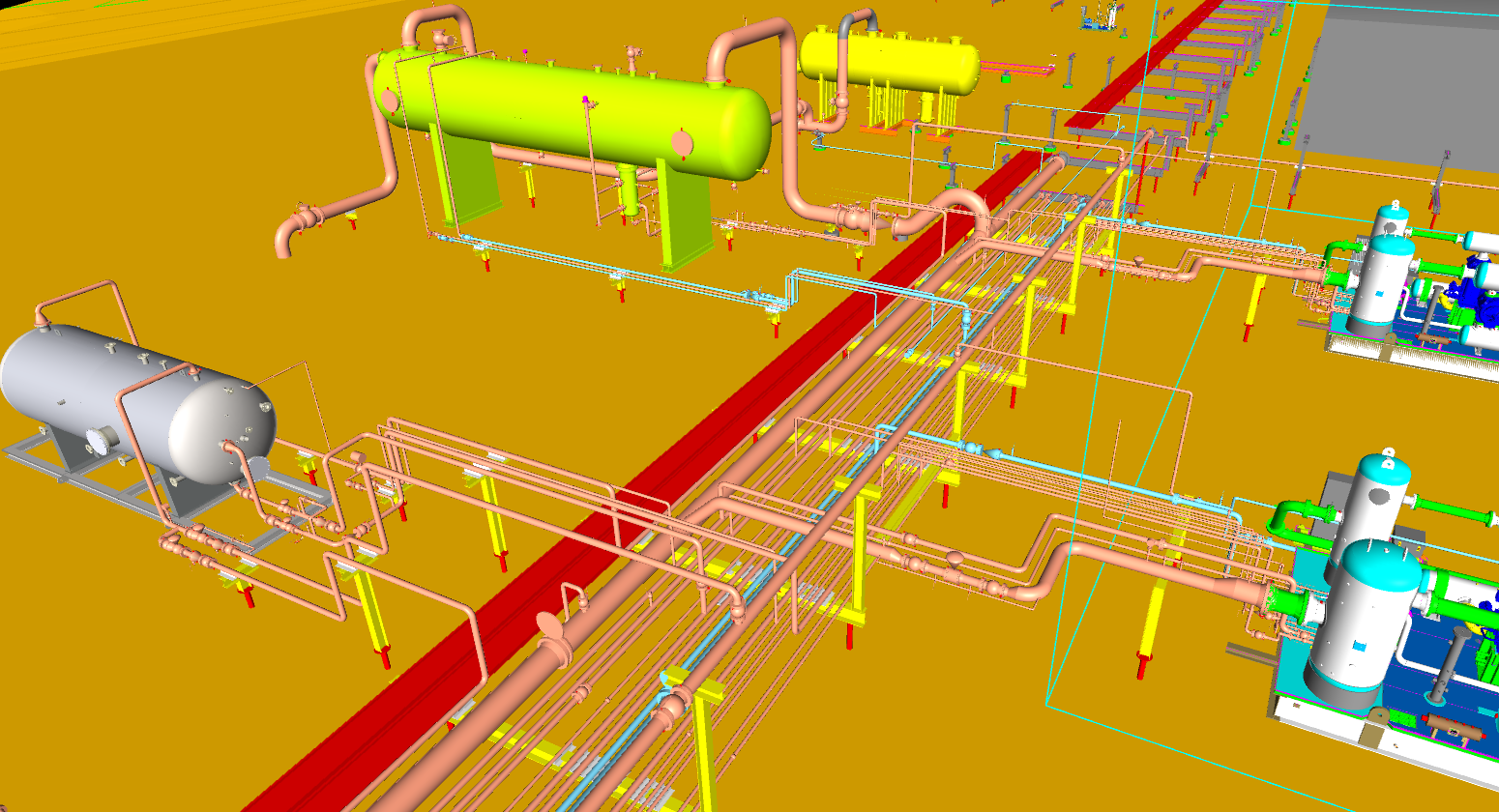

• 3D modeling

• Construction packages for electrical, mechanical, and civil bids

THE SOLUTION

Engineering

✓ Up-to-date engineering package for the site

✓ Future compressor additions require no additional mechanical design

✓ Developed plan for short shutdown window for tie-ins

Operations

✓ Addressed issues with high-pressure drains to VRU

✓ Improved isolation and access to compressor packages

✓ Consolidated planned equipment for a two-inlet design to a single inlet