CARBON CAPTURE, UTILIZATION & STORAGE

Metal Organic Framework – Post-Combustion Carbon Capture

LOCATION: Canada

MARKET: CO2 Capture & Storage

THE CHALLENGE

Testing of new technologies for capturing CO2 requires the design of the capture facility and alignment with the marketing of the CO2. A developing proprietary process is rapid cycle Temperature Swing Adsorption (TSA) systems using advanced structured adsorbents that can produce a high-purity CO2 stream. The CO2 can be pipelined for use in Enhanced Oil Recovery (EOR) production programs or utilized by CO2 consumers. The goal of pilot facilities is to demonstrate the performance and operational requirements to deploy this new technology.

THE SOLUTION

Combustion gas streams can consist of 10% CO2, 18% H2O, 70% N2, and 2% O2 with impurities

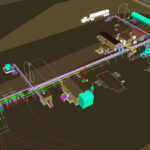

- Execute the detailed design based on the supplied Process Design Basis

- Plot plan & P&ID development

- Civil designs & pile foundations

- Structural steel & skids

- Electrical, Instrumentation & Controls

- Procurement

- Pipeline route maps

- Locate all TSA system tie-ins

- Evaluate utilities

- Instrument air & fuel gas

- Feed & wastewater

- Power loads

- Design and commission control system with data acquisition and storage

- Generate Standard Operating Procedures for normal, controlled, and emergency modes of operations and shutdowns

THE CAPABILITY:

- TSA systems can capture 30 MTPD of CO2 with recovery and purity of 90%

- TIC of $18MM for installation of the TSA system

- Demonstrate performance and operational results from lab to pilot scale

- Optimize CO2 recovery using different adsorbents