AMINE VENT DISPERSION

Reducing Hazardous Gas Conditions

LOCATION: Douglas, WY

MARKET: Emissions Reduction / ESG

THE CHALLENGE

The Client was experiencing shutdown trips in their amine processing area from hydrogen sulfide sensors due to increased H2S in the inlet gas. During calm ambient conditions (e.g. no wind), the gas from the vent stack can migrate to grade and present safety concerns for the onsite operators and exceed the NIOSH REL and OSHA PEL 10-minute exposure limits.

THE SOLUTION

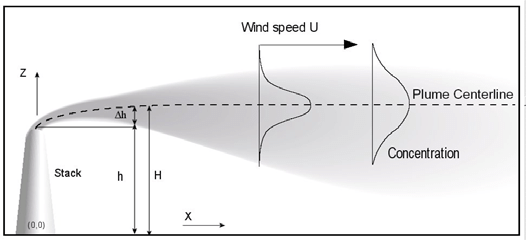

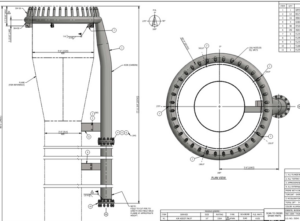

CANUSA EPC evaluated various options from thermal oxidizers, vent stack blowers, and H2S scavengers as solutions to reduce the instances where H2S was causing facility shutdowns. The solution selected was a modified blower vent tip system to increase the velocity of the exit gas to elevate the concentrated gas high enough to disperse to non-detectable levels by the time it reached safety sensors.

Engineering:

- Blower specification

- Dispersion modeling

- Electrical system additions

- Vent structural steel design for blower

Procurement:

- VFD Specification

- Blower package evaluation

- Dispersion modeling

- Construction package bids

THE RESULTS

Reduction in ground measurements of H2S exceeding the 20 ppm sensor shutdown

- Reduced conditions where operators are exposed to H2S limits above OSHA

- Mitigated instances of shutdown related to inadequate dispersion of H2S